Water Cooled Inverter Scroll Chiller provides a smooth and efficient solution to the application where the cooling requirement continues to vary during the day. The inverter based scroll compressor can automatically vary its output so as to maintain constant temperatures with a minimum wastage of power as well. The water-cooled condenser allows the operation to continue and enhances the heat removal, particularly when a system is in operation.

This chiller is suitable in the process lines, machine cooling systems, and controlled temperature areas where consistency is important rather than maximum productivity. The system is designed using simple controls, strong components, and effective heat exchange enabling it to operate without much noise and barely any maintenance. Having a flexible cooling control and reliable water-cooled performance, Water Cooled Inverter Scroll Chiller permits users to attain a steady outcome and reduces the operating expenses.

Aquatech Plus offers one of the best Water Cooled Inverter Scroll Chiller in India, and this is a reliable cooling system that finds application in industries, commercial and process cooling. These chillers integrate high-tech inverter-powered scroll compressors, along with smart control systems to ensure tight temperature control and reduction in energy usage.

Inverter scroll technology enables the unit to equalise the changing cooling loads, unlike conventional chillers, so it can continue to perform the same even in the presence of varying operating conditions. This suits them well in places like pharmaceutical production, data centres, food processing, and HVAC systems, which require a very high degree of temperature control.

Aquatech Plus is one of the most successful Water Cooled Inverter Scroll Chiller Manufacturers in India; we focus on innovation, precise engineering and quality. We produce our units according to ISO 9001:2015, CE and RoHS requirements, being the most reliable and meeting the requirements of the international certifications.

Aquatech Plus is a reputable Water Cooled Inverter Scroll Chiller Suppliers in India, which offers cooling solutions of high performance and complete technical assistance during the procurement process.

Aquatech Plus is also dealing with professional networks of dealers and this makes us major Water Cooled Inverter Scroll Chiller Dealers in India. We have a dealer network that easily reaches high-quality chillers and technical assistance during installation and maintenance.

Aquatech Plus is a known Water Cooled Inverter Scroll Chiller Exporters in India which also provides high-quality chillers to the global markets. Our export-grade units are energy-efficient, reliable and globally available, making them ideal for any application in various industries.

Aquatech Plus is a company that will be distinguished in the market because of its quality, technology and customer satisfaction. Our chillers are designed to integrate both modern engineering and eco-friendly and energy-saving design.

Are you willing to have your cooling system upgraded with a Water Cooled Inverter Scroll Chiller by Aquatech Plus? Our group will offer customized services to meet your special requirements whether they be efficiency, reliability or energy conservation.

| Description | Units | FMWCVS-13R | FMWCVS-26R | FMWCVS-39R | FMWCVS-52R | FMWCVS-65R | FMWCVS-78R |

|---|---|---|---|---|---|---|---|

| Nominal Cooling Capacity | TR | 13 | 26 | 39 | 52 | 65 | 78 |

| Quantity of Compressors | Nos. | 2 | 2 | 3 | 3 | 3 | 4 |

| Type | - | Hermetically Sealed Scroll | |||||

| Motor Type | - | Refrigerant Cooled, 3 Ph, 2 Pole Squirrel Cage Induction Motor | |||||

| Operating Speed | RPM | 2900 | |||||

| Electrical Power Supply | - | 400V (±10%), 3Ph, 50Hz | |||||

| Flooded – Condenser | |||||||

| Tube Material | - | IGT Copper | |||||

| No. of Pass (Water Side) | Nos. | 4 | 4 | 2 | 2 | 2 | 2 |

| No. of Refrigerant Circuit | Nos. | 2 | 2 | 2 | 2 | 2 | 3 |

| DX Cooler | |||||||

| Tube Material | - | Integral Finned Copper Tubes | |||||

| No. of Pass (Ref. Side) | Nos. | 4 | 2 | 2 | 2 | 2 | 2 |

| No. of Refrigerant Circuit | Nos. | 2 | 2 | 2 | 2 | 2 | 3 |

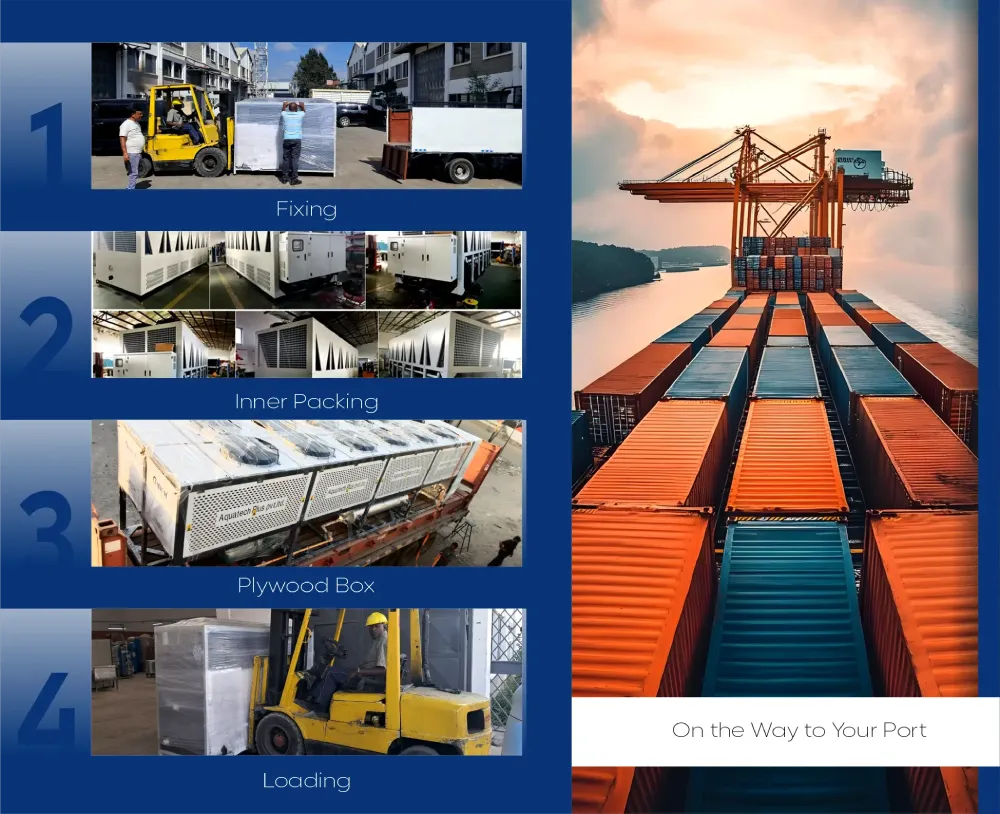

We have a uniform workflow in packaging and logistics that is export-wise, which prepares all our products except that they are safe in handling and delivery with no damages in India and other countries. Every phase is also thought out to cushion equipment against vibration, impact, and moisture risks in addition to long-distance transportation risks. The same is done to water chillers, air chillers and all other products that we produce and supply.

The process starts with mechanical repair of the unit of the product. The industrial quality fastening is used in all internal assemblies, critical parts, piping, and electrical parts. Moving components are fixed, and vibration-sensitive sites are fixed to avoid the mechanical stress during the transportation.

Objective: Avoid internal movement, vibration breakage, and alignments during transportation.

Once the repair is done the product is inner-packed with moisture-proof and shock absorbing materials. Foam padding, stretch film and cushioning materials are used as protective layers to cover all the exposed areas and all those components which are sensitive.

Objective: Dust, humidity, surface abrasion, and small mechanical shocks.

The product is packed in a specially designed heavy-duty plyboard box which is produced depending on its size and weight. The casing of the plywood is strengthened to resist the weights of the stacking, forklift operation and the transportation strain over long distances. When exporting goods, the packing is done to comply with the shipping and container loading requirements by the international community.

Objective: Optimal security on the outside and the requirements of the domestic and export logistics.

The product is loaded to the trucks with the use of cranes or forklifts, in accordance with good lifting and load-sharing practices. The delivery is then by road under conditions of control. In the case of domestic clients, the truck will go straight to the facility of the customer.

Objective: Loading and stable transportation on the road.

Whereas in international deliveries, the shipment is taken out of our plant to the Indian port. Pre-port entry All the export documentation, labeling and compliance checks are done before port entry.

Our logistics partners are reputable and trusted individuals like EMS, DHL Express, and FedEx Express who help us to have an easy time moving the ports and handling the exports.

Goal: The port handling and export preparation are smooth.

After clearance in the port, the product is delivered through sea freight into the destination port of the client. The packaging is to maintain a long transit period, container handling and a fluctuating weather pattern.

The international deliveries are also arranged with the help of the existing world logistics systems, the EMS, DHL Express and FedEx Express, which guarantee the safe and timely delivery.

Purpose: Achieve international delivery with low levels of transits.

A clear packaging and transportation procedure would assure that all products will be delivered to the clients in working conditions, lessen installation and commission problems, minimize the risk of transit damage, and facilitate hassle-free domestic and foreign delivery.

This is our standard operating procedure and is used in the process of packaging and transportation of all our products. Although the central process is the same, a different method can be used to pack the products, depending on the product size, weight and the destination to which the product is to be shipped.

This packaging and transportation workflow represents our standard operating process and is uniformly followed across our entire product range. The steps outlined above are not product-specific but define our company-wide logistics and export handling standards.

To maintain consistency, safety, and compliance, this process is intentionally displayed across all relevant product pages under the Packaging & Transportation section. While the framework remains the same, actual packing materials, box dimensions, and handling methods may vary depending on product size, weight, and shipment destination.

From an operational standpoint, this approach ensures:

From an SEO and documentation perspective, this section is used to clearly communicate our established logistics protocol, not to repeat marketing content. Each product page focuses on its unique specifications and applications, while this section defines our common logistics standards.

A water-cooled inverter scroll chiller is a type of cooling system which utilises a scroll compressor with inverter drive and a water-cooled condenser to cool water to use in HVAC or industrial purposes.

An inverter scroll compressor changes its speed along with the cooling demand, thus saving energy. Inverters maintain a constant temperature, reduce electrical spikes and increase efficiency when the load is partially used compared to the traditional compressor, which cycles on or off.

Yes, you can put several water-cooled chillers in parallel to achieve more cooling or redundancy. This scalable system enables a facility to add capacity as it becomes necessary without overloading a single unit, leading to increased efficiency and reliability.

When well maintained and kept, these chillers have a lifetime of 15-20 or even more. The lifespan is related to the quality of water used, the condition of the operations, frequent repair and maintenance of compressors, pumps, and control systems.

Yes, several water-cooled chillers may be connected in parallel to increase cooling or offer redundancy. This modular design enables the facilities to add capacity on short notice without overstating a single unit, enhancing efficiency and reliability.

Most modern water-cooled scroll chillers use R-410A, R-32, or R-134a, which are environmentally safer, have low ozone depletion potential and maintain efficient thermodynamic performance which ensures compliance with global environmental standards and regulations.

We carry a specified warranty and effective after sales services to all goods provided by us. Our warranty and service system will be aimed at long-term performance, reliability in terms of work, and peace of mind of our clients, both domestic and international.

Every product has a standard warranty of manufacturing defects dating back to the dispatch date or the date of installation, as existing. The warranty includes the defects to the quality of material and workmanship in the normal operation condition.

There are various warranty terms based on the product category, model, application and environment of use. Specifics on warranty period and coverage are provided in detail during the confirmation of orders or issue of invoice.

Warranty is not applicable on damages caused by:

Our technical support provides our clients with instructions on how to install, answer technical questions as well as basic troubleshooting. Depending on where the project is located, support is accomplished by providing documentation, remote assistance or by organizing services with service partners.

We assist both domestic and foreign clients with well-organized contact and export documentation. In the case of international customers, technical support and service management are offered remotely to have a comfortable functioning and prompt problem resolution.

There is a process in which service requests are processed. When we get a support request, we examine the problem and determine the warranty eligibility and suggest a remedy. The response timelines can be different depending on the product, location and availability of the components.

The above warranty and support terms are the standard policy which we use in our whole product line. Particular product-level warranty information might vary and are provided independently when taking orders.

This Warranty & Support section represents our standard company-wide policy and is consistently applied across our complete product range. The content is intentionally displayed on multiple product pages to communicate uniform warranty coverage, service terms, and support procedures.

While the core policy remains the same, actual warranty duration, coverage scope, and service conditions may vary by product model, application, and operating environment. Product-specific warranty details are shared separately at the time of order confirmation or documentation.