A water chiller system that is developed to offer efficient and dependable cooling of water needed by industries and businesses. It operates by extracting the unwanted heat in process water and pumping chilled water to equipment or machineries or systems that need to maintain controlled operating temperatures. A water chiller system can be used to ensure more accuracy of processes, protect vulnerable parts and ensure overheating does not occur during uninterrupted operation by maintaining a consistent cooling temperature.

Water chiller systems are common in the manufacturing plants, processing industries, HVAC systems, laboratories and commercial facilities where temperature regulation is very important. These systems have been designed to run on a 24-hour basis, thus helping in performance energy efficiency, shorter downtimes, and durability. Water chiller systems are important in ensuring efficient operations and the optimal performance of any business environment under high demand due to their precise temperature regulation and sound structure.

A Water Chiller System is a necessary cooling system used in various industries because it helps with maintaining processes, equipment, and working temperatures. This is used to remove water, heat, and recirculate chilled water to ensure stable, efficient, and uninterrupted operations.

Water chiller System Manufacturers in India deal with designing, engineering, and manufacturing cooling systems to address the needs of industrial, commercial, and HVAC requirements. The process of manufacturing entails the correct choice of compressors, heat exchangers, refrigerants, and control systems to guarantee predictable performance and energy savings, in addition to a durable working life under consistent working conditions.

A water chiller system will run on a closed-loop refrigeration cycle to ensure steady and constant cooling:

This type of cycle guarantees effective cooling even in high ambient and peak load conditions.

Water Chiller System- Air Cooled.

Relies on the surrounding air to dissipate heat; hence, it is the most suitable in areas with limited water supply. These systems are simple to install, and there is little maintenance.

Water Cooled Water Chiller System

These systems have cooling towers and were designed for high capacity and continuous operation, providing a higher efficiency with large setups in industries.

Chiller System Water Process.

Their design is specifically to be used in machinery and process cooling so that a stable production temperature is controlled.

HVAC Water Chiller System

Applied in centralized air conditioning in corporate buildings, hospitals, lodges, and even industrial premises.

A reliable Water Chiller System Suppliers in India is a guarantee of the availability of standard and tailored cooling systems in various industries. They are also responsible for logistics, timely delivery, and technical support to assist customers in choosing the most appropriate chiller system.

We are reputable Water Chiller System Dealers in India with the operation of real and performance-tested milk cooling systems. We have dealer support, which specializes in application-based recommendations, which will mean that the customers will have access to the most appropriate water chiller systems based on their operational needs and location.

A trusted Water Chiller System Exporters in India offers the best quality cooling systems to the international markets. The systems are manufactured to be in line with the international electrical, safety, and performance standards so as to have a good working performance in the various climates.

Out-of-control heat may lead to damage to equipment, defects, and loss of production. An efficient water chiller system will provide a smooth-running system, reduced cost of maintenance, and excellent performance in the harsh industrial conditions.

When you are selecting a water chiller system, the chiller's capacity can influence the decision. As it is dependent on the environment, process requirements, and the time it is going to operate. Professional guarantees optimum operation and long-term efficiency.

Obtain professional advice and technical assistance, as well as customized cooling solutions for your application.

| Paramete | Specification |

|---|---|

|

Cooling Capacity Range |

From small tonnage to high-capacity industrial systems |

|

Operating Temperature |

+5°C to -20°C (application dependent) |

|

Chiller Configuration |

Air-cooled / water-cooled |

|

Compressor Type |

Scroll / Screw / Reciprocating / Centrifugal |

|

Condenser Type |

Air cooled / Shell & tube / Evaporative |

|

Evaporator Type |

Shell & tube / Plate heat exchanger |

|

Refrigerants |

R134a, R407C, R410A, R404A, R32 |

|

Power Supply |

380V / 415V / 480V – 3 Phase, 50/60 Hz |

|

Control System |

PLC / Microprocessor-based |

|

Safety Features |

HP/LP switch, overload protection, phase protection |

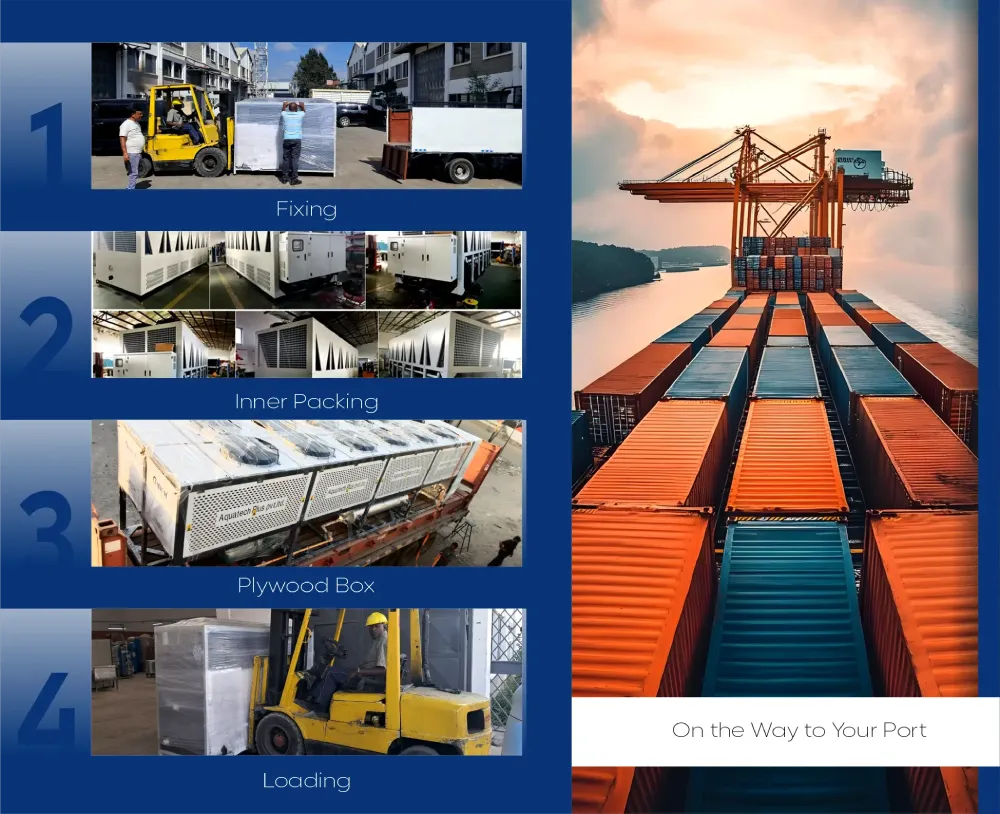

We have a uniform workflow in packaging and logistics that is export-wise, which prepares all our products except that they are safe in handling and delivery with no damages in India and other countries. Every phase is also thought out to cushion equipment against vibration, impact, and moisture risks in addition to long-distance transportation risks. The same is done to water chillers, air chillers and all other products that we produce and supply.

The process starts with mechanical repair of the unit of the product. The industrial quality fastening is used in all internal assemblies, critical parts, piping, and electrical parts. Moving components are fixed, and vibration-sensitive sites are fixed to avoid the mechanical stress during the transportation.

Objective: Avoid internal movement, vibration breakage, and alignments during transportation.

Once the repair is done the product is inner-packed with moisture-proof and shock absorbing materials. Foam padding, stretch film and cushioning materials are used as protective layers to cover all the exposed areas and all those components which are sensitive.

Objective: Dust, humidity, surface abrasion, and small mechanical shocks.

The product is packed in a specially designed heavy-duty plyboard box which is produced depending on its size and weight. The casing of the plywood is strengthened to resist the weights of the stacking, forklift operation and the transportation strain over long distances. When exporting goods, the packing is done to comply with the shipping and container loading requirements by the international community.

Objective: Optimal security on the outside and the requirements of the domestic and export logistics.

The product is loaded to the trucks with the use of cranes or forklifts, in accordance with good lifting and load-sharing practices. The delivery is then by road under conditions of control. In the case of domestic clients, the truck will go straight to the facility of the customer.

Objective: Loading and stable transportation on the road.

Whereas in international deliveries, the shipment is taken out of our plant to the Indian port. Pre-port entry All the export documentation, labeling and compliance checks are done before port entry.

Our logistics partners are reputable and trusted individuals like EMS, DHL Express, and FedEx Express who help us to have an easy time moving the ports and handling the exports.

Goal: The port handling and export preparation are smooth.

After clearance in the port, the product is delivered through sea freight into the destination port of the client. The packaging is to maintain a long transit period, container handling and a fluctuating weather pattern.

The international deliveries are also arranged with the help of the existing world logistics systems, the EMS, DHL Express and FedEx Express, which guarantee the safe and timely delivery.

Purpose: Achieve international delivery with low levels of transits.

A clear packaging and transportation procedure would assure that all products will be delivered to the clients in working conditions, lessen installation and commission problems, minimize the risk of transit damage, and facilitate hassle-free domestic and foreign delivery.

This is our standard operating procedure and is used in the process of packaging and transportation of all our products. Although the central process is the same, a different method can be used to pack the products, depending on the product size, weight and the destination to which the product is to be shipped.

This packaging and transportation workflow represents our standard operating process and is uniformly followed across our entire product range. The steps outlined above are not product-specific but define our company-wide logistics and export handling standards.

To maintain consistency, safety, and compliance, this process is intentionally displayed across all relevant product pages under the Packaging & Transportation section. While the framework remains the same, actual packing materials, box dimensions, and handling methods may vary depending on product size, weight, and shipment destination.

From an operational standpoint, this approach ensures:

From an SEO and documentation perspective, this section is used to clearly communicate our established logistics protocol, not to repeat marketing content. Each product page focuses on its unique specifications and applications, while this section defines our common logistics standards.

Water chiller systems are preferred over direct cooling systems because cooling is provided for numerous machines and/or HVAC systems the water chiller system has a uniform over direct cooling system temp, higher efficiency, reduced stress on the equipment, and greater reliability.

The ideal time to incorporate a water chiller system is during the planning or expansion stage of a business, prior to reaching peak production. Installing the system early on helps in the accurate sizing of the system, the seamless integration with other processes or HVAC systems, and the avoidance of disruptions to business operations down the line.

The control system, pump, and the each system component that deals with one of the three main refrigerant/hear exchange/water distribution processes: compressor, evaporator, and condenser; and expansion valve.

Process instability, downtime, and loss of equipment and connected systems are all consequences of an undersized chiller leading to system wear, increased energy costs, compressor cycling, and insufficient cooling.

A water chiller system includes the chiller unit, chilled water pumps, piping network, expansion tank, and end-use equipment, all working together to deliver stable and efficient cooling.

The system continuously circulates chilled water and adjusts compressor operation through sensors and controllers, ensuring accurate temperature control even during changing load conditions.

We carry a specified warranty and effective after sales services to all goods provided by us. Our warranty and service system will be aimed at long-term performance, reliability in terms of work, and peace of mind of our clients, both domestic and international.

Every product has a standard warranty of manufacturing defects dating back to the dispatch date or the date of installation, as existing. The warranty includes the defects to the quality of material and workmanship in the normal operation condition.

There are various warranty terms based on the product category, model, application and environment of use. Specifics on warranty period and coverage are provided in detail during the confirmation of orders or issue of invoice.

Warranty is not applicable on damages caused by:

Our technical support provides our clients with instructions on how to install, answer technical questions as well as basic troubleshooting. Depending on where the project is located, support is accomplished by providing documentation, remote assistance or by organizing services with service partners.

We assist both domestic and foreign clients with well-organized contact and export documentation. In the case of international customers, technical support and service management are offered remotely to have a comfortable functioning and prompt problem resolution.

There is a process in which service requests are processed. When we get a support request, we examine the problem and determine the warranty eligibility and suggest a remedy. The response timelines can be different depending on the product, location and availability of the components.

The above warranty and support terms are the standard policy which we use in our whole product line. Particular product-level warranty information might vary and are provided independently when taking orders.

This Warranty & Support section represents our standard company-wide policy and is consistently applied across our complete product range. The content is intentionally displayed on multiple product pages to communicate uniform warranty coverage, service terms, and support procedures.

While the core policy remains the same, actual warranty duration, coverage scope, and service conditions may vary by product model, application, and operating environment. Product-specific warranty details are shared separately at the time of order confirmation or documentation.